Dongtai Yaoqiang Machinery Manufacturing Co., Ltd. is located in

the beautiful Taihu Lake - Wuxi, Jiangsu, and its manufacturing

base is located in the wetland capital - tangyangxinhong Industrial

Park, Dongtai, Jiangsu, covering an area of 20 mu. It is a company

with modern industrial plant layout and large processing equipment.

The company adheres to the management concept of "people-oriented,

customer first", optimizes the modern management system, improves

the customer service system, promotes the brand of high-tech

enterprises, and creates the production base of heavy complete

welding equipment in China. The company relies on welding, cutting,

machinery, numerical control, electronics, electrical automation

control and other professional, with many years of professional and

technical personnel engaged in engineering equipment, relying on

the technical achievements of well-known institutions at home and

abroad, carries forward the spirit of teamwork, and quickly

provides and solves technical services including production layout,

process analysis and engineering equipment for different users.

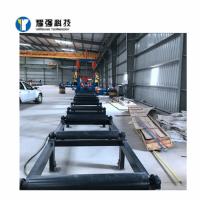

The main products are: cutting / groove / assembly / welding /

correction, steel structure welding equipment, H-beam production

equipment, automatic welding equipment and other equipment. There

are operating machine series, positioner series, roller frame

series, milling machine series, CNC flame / plasma cutting machine

series, wind tower tube group welding complete sets of equipment.

Light steel production line has many straight bar cutting machine,

assembly machine, gantry welding machine, H-beam flange

straightening machine, shot blasting machine. Heavy steel welding

production line equipment, box girder welding production line

equipment and supporting processing equipment.

The company's products are diversified and specialized, involving

industries such as ship bridges, electric power repair, steel

structure beams and columns, engineering machinery, locomotives,

boilers and pressure vessels, wind power generation, petrochemical

machinery, coal mining machinery, metallurgical environmental

protection equipment, shipyard heavy machinery, etc. At present,

the company's products not only meet the domestic market, but also

exported to Southeast Asia, Australia, America and other foreign

markets.