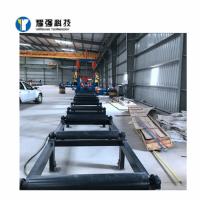

High Grade Welding Equipment 3 Fonctions Welding Machine for H beam

assembling straightening and welding

The H steel production line is used for welding the production of H

steel. The production line can continuously complete the process of

setting up, welding, orthodontics and discharging T-and H-section

steel in the production process. The production process is

controlled by program, and the welding speed is adjusted by

frequency conversion technology.

This machine is suitable for use in smaller workplaces, and is

affordable and functional. It consists of 3 H beam manufacturing

processes: assembly - Welding - rectification. It can produce

symmetrical and asymmetric cross sections of H and T beams. At the

same time, it can complete the following procedures: initial and

final assembly of beams, butt submerged arc welding of beams in

vertical state, and correction of welding deformation (mushroom

shape) of beams. The automatic assembly machine is equipped with

flux circulation system to reduce flux consumption. The assembling

and welding of H beam is automatic mode. In production, the

movement speed of the beam can be adjusted by means of

program-controlled monitor, so as to ensure the quality of the

weld.

I. equipment composition:

1. main engine: including H steel assembly, welding, correction,

roller conveyance, etc.

2. electronic control system: main control cabinet, PLC program

system settings, and touch screen display lights.

3. groups of institutions: Web clamping, wing plate clamping and

lower pressing device.

4. lifting mechanism: input roller device

5. discharging mechanism (including lifting mechanism 2): output

roller device

6. hydraulic system: oil cylinder, hydraulic pump station and high

pressure tubing lamp.

7. aligning mechanism: cylinder lifter

8. wire feeder assembly:

9. work platforms and escalators: accessories, etc.

10. welding power source two: power supply, control box, welding

cable, control cable, etc. 11., two sets of flux recovery

equipment: vortex air pump, recovery device, funnel, etc.

| Model | web height | web thickness | welding and straightening speed | flange width | flange thickness | overall power |

| YQPJ1000 | 1000mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

| YQPJ1200 | 1200mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

| YQPJ1500 | 1500mm | 6-16mm | 0.35-3m/min | 200-800mm | 6-20mm | 13.4kw |

Our company:

Jiangsu Yaoqiang Technical Group is a dealers holding type and

high-tech enterprise. It mainly supply welding, cutting, milling,

pipe producing production line as well as electrical automation

equipment. The group consists of Jiangsu Silver Coast International

Trading Development Co., Ltd (locate in Wuxi)& Dongtai Yaoqiang

Mechinery Manufacture Co., Ltd. While Wuxi company, which is

located in National technical industry park, i. e.The Wuxi Liandong

U Valley, besides the Taihu lake with beautiful scenery and

renowned humanities, is mainly focus on enterprise blue print,

R&D, marketing,trading, management and finance. The Dongtai

plant is devoted to technics, manufacture, process control, test

and after-service, which locates at Dongtai Tangyang Xinhong

Machinery industry park, in the wet land area off the seashore of

Huanghai.

So we are manufacturer and trader. The Wuxi part is for trading and

Dongtai part is for producing.

Here we make a promise to you all: we will offer you the products

with the ideal price and good quality.

If you have any problems or you are interested in our products,

Please contact me via Email or following ways:

| NO. | MODEL | YQPJ1500 |

| 1 | Web height | 1500 mm |

| 2 | Web thickness | 6~32 mm |

| 3 | Flange width | 150~800 mm |

| 4 | lange thickness | 6-40 mm |

| 5 | H beam length | 4000~15000 mm |

| 6 | Dimensional adjustment system | Separate, mechanical |

| 7 | welder | 2 sets of Mechanical submerged arc welding machine |

| 8 | Welder Power | 2×75KW |

| 9 | Welder type | automatic submerged arc welding |

| 10 | weld speed | 0-1000 mm/min |

| 11 | Weld speed adjustment | level and smooth |

| 12 | Head angle adjustment | ±45°±12.5 |

| 13 | Pressure of hydraulic system | ≤10 Mpa |

| 14 | Automatic welding cycle system | 2sets |

| 15 | Flux | 2×100 kg |

| 16 | Total power | 24 kw Except for welding power supply |

| 17 | Overall dimensions (L * w * h) | 30000×3270×5150 mm |

| weld size(mm) | wire diameter(mm) | welding current (A) | welding voltage(V) | welding speed(mm/min) |

| 4 | 3 | 350~370 | 28~30 | 880~910 |

| 6 | 3 | 450~470 | 28~30 | 900~960 |

| 4 | 480~500 | 28~30 | 960~1000 |

| 8 | 3 | 500~530 | 30~32 | 730~760 |

| 4 | 670~700 | 32~34 | 800~830 |

| No. | Name | |

| 1 | welder | MZ-1000(optional,also can use CO2 welder) |

| 2 |

Welding machine control box | MZ-1000 |

| 3 |

Inverter manufacturers | 11KW,2.2KW HUICHUAN |

| 4 |

Major electrical equipment manufacturers | SIEMENS, OMRON (Japan) |

| 5 | Hydraulic parts manufacturers | TAIWAN |

| 6 | main motor supplier |

NANTONG |

| 7 | Wing web centering motor | 2 sets NINGBO |

| 8 | Main reducer manufacturers |

CHANGZHOU |

| 9 | recovery equipment |

2 sets WUXI |

Supply matching:

Frame;

Console;

Pre assembled mechanism;

Feed roller table;

Delivery roller table;

2 sets of welding machine;

Hydraulic station;

Mushroom shaped deformation correcting mechanism for beam;

Welding console -2 sets for wire feed mechanism;

Wire box -2 parts;

Hydraulic hose;

Flux cycle system ----2 set;

Work platform and ladder;

The supply does not include:

1. foundation;

2. connect to the power and air source of the equipment;

3. equipment grounding;

4. welding wire or flux etc.